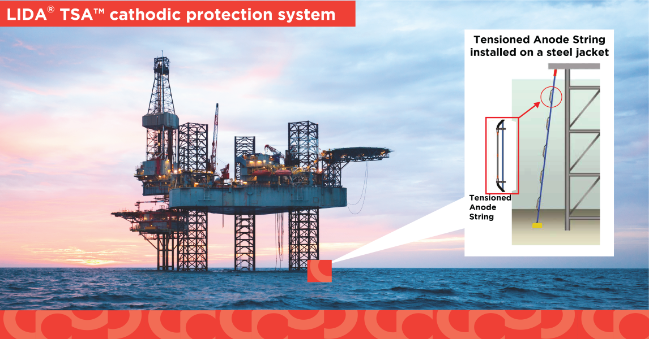

All offshore structures, including platforms (fixed and semi-submersed), piers and docks require a comprehensive, ongoing plan to mitigate corrosion caused by the seawater environment. Over time, and as the structures age, the original sacrificial cathodic protection systems require refurbishment in order to extend the useful life of the structure. This life extension requirement can range from 5 to 20 years.